Written by David Tucker

David Tucker is a Project Director for the Environmental Finance Center.

In our work with the Smart Management for Small Water Systems project and other programs, the Environmental Finance Center has seen initiatives by drinking water and wastewater systems around the country take advantage of renewable energy options to help reduce their energy and power costs, often through some kind of third-party financing arrangement, such as a power purchase agreement (PPA). For example, here in our home state of North Carolina, the City of Raleigh leases land to a private solar developer who installed a 250 kilowatt (kW) solar photovoltaic (PV) array at the City’s E.M. Johnson Water Treatment Plant a few years ago, and the developer sells the electricity to the local power utility. Solar power examples such as these are becoming more common at water utilities, but you may not have heard yet about the opportunities for micro-hydro power for water utilities, another potential source of clean, “green,” renewable energy, as well as additional revenue generating opportunities.

While water utilities will probably never be in the business of generating electric power at the level of a large hydroelectric dam, they may have some interesting options in the “micro-hydro” category. The difference in such categories is illustrated by this chart, courtesy of Steven Jones of the engineering firm Hansen, Allen, and Luce, who recently presented on this topic at an Environmental Finance Center Network workshop on energy management for small water systems in Utah:

| Hydro Power Category | Nameplate Capacity in Megawatts (MW) or Kilowatts (kW) |

| Large Hydro Power | >30 MW |

| Small Hydro Power | <30 MW but >1 MW |

| Mini Hydro Power | <1 MW but >100 kW |

| Micro Hydro Power | <100 kW but >10 kW |

| Pico Hydro Power | <10 kW |

What sort of options do water utilities have to generate micro-hydro power as an outgrowth of their water system operations? In general, there are three categories to consider:

- pressure regulator stations,

- spring flows into the water system, and

- any water with a higher head. (“Head” is the pressure exerted by the weight of water above a given point, due to gravity, such as may happen in an elevated water storage tank, or between a reservoir and areas served at lower elevations)

In this article we will focus a bit more on the first of these three, pressure regulator stations, as an opportunity for micro-hydro power generation. However, a water utility might incorporate two or all three of these approaches at various points in their system.

All three of these micro-hydro generation technologies have their uses, and have been applied at various utilities around the world already. But water sources for water utilities may vary considerably. Some may not have reservoirs, for example – many smaller North Carolina water utilities do not. Others may not have spring flows, or even if they do, those spring flows may be low in dry seasons, making it difficult or impossible to run micro-hydro power generation turbines except for a few months per year – which, in turn, may make the payback periods unacceptably long on such investments. But most if not all water utilities have a need periodically to relieve pressure on parts of their distribution systems, in order not to exceed safe pressure levels — hence the need for pressure regulator stations.

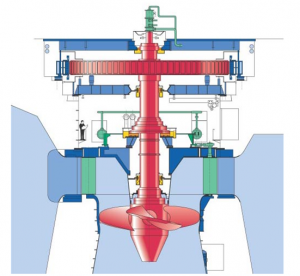

Depending on the situation, a variety of micro-hydro turbine technologies are available. For an elevated storage tank application with low head and high volume of flow, a Kaplan Turbine might be used:

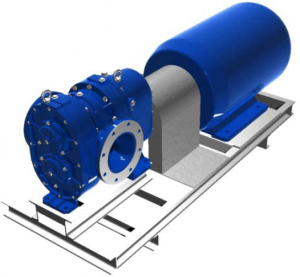

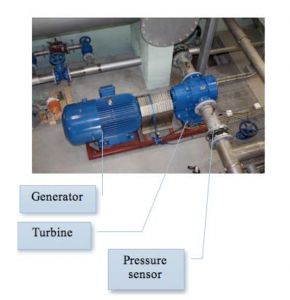

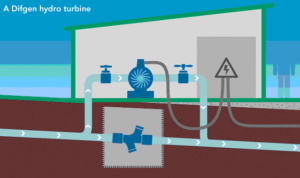

However, utilities of various descriptions and sizes will have the need to periodically relieve excess pressure by opening pressure regulator valves (PRVs) at various points in their distribution systems. That outflow of pressure from a higher to a lower state represents an as-yet-untapped opportunity to generate electricity by taking advantage of the flow through this pressure gradient. Hence, a new technology pioneered in Europe (but not yet introduced to the United States as of this writing) is the Difgen Hydro Turbine – doubtless named in relation to generating electricity from a differential in pressure levels.

As explained by Hansen, Allen, and Luce, the DifGen Hydro Turbine (DHT) is a volumetric displacement turbine with a rotating barrier between the upstream and downstream fluids. A fixed volume of fluid is dosed through the turbine for each revolution. By applying a negative load, differential pressure is dynamically controlled. The negative load is an electric power generator, controlled by a variable frequency drive (VFD).

In other words, a system could use a DHT coupled with a VFD to regulate the pressure and flow whenever it needs to bleed off some excess pressure in the system – which might happen any time of year, in a wet or a dry season. This could be an opportunity to generate electric power for the system itself, or to sell power to a local electric utility through a prearranged contractual arrangement. The initial capital cost also might be reduced through a third-party financing arrangement, such as a PPA, which is described in a solar PV context for a college or university campus in this previous blog posting. Whether using a third-party financing option or not, the years to payback for this technology might be reduced by being able to run the DHT many days per year, though with the up-front capital cost is still unclear for a future American market.

Looking back to micro-hydro technology already in operation in the U.S., the Orodell Station in Boulder, Colorado, operates a Francis Turbine with a nameplate power generation capacity of 180 kW, using a water head of 413 feet (179 PSI), an average water flow of 3,100 gallons per minute (gpm), and producing enough power for 51 average American homes. With an estimated capital cost of between $440,000 and $540,000, and an average number of days of operation of 125/year, this generates approximately $18,600 in revenue from electricity sales via a PPA arrangement. This equates to a simple payback period of 24-29 years (not accounting for the time value of money).

Such a payback period would be considered too long by many people. However, using this data on Boulder’s Francis Turbine, and lacking project economics data on the new DifGen technology, we could make the following rough estimate. If the capital cost of a DifGen Hydro Turbine of comparable capacity were similar to the cost of Boulder’s Francis Turbine, but if the DifGen could be operated for 365 days per year instead of 125 (since pressure regulation in a water system may well be a daily activity), then the annual electric sales (or an on-site use / avoided cost of buying power from the grid, depending on the situation) could potentially increase to $54,300/year, reducing the simple payback period to a much more doable 8 years. Perhaps the payback period could go even lower if demand (i.e. power) charges were reduced as well for the water utility in question. And indeed, due to the claimed greater reliability, technologies like DifGen which generate electric power from pressure reduction may become a lower cost per kilowatt application of renewable energy for water utilities in the near future than solar or wind, though they too are becoming more affordable. Only time will tell!

Many thanks once again to Steven Jones of Hansen, Allen and Luce for much of the data for this article.

Micro-turbines may be eligible for low-cost financing with Qualified Energy Conservation Bonds (QECBs), a program authorized as part of ARRA if they are at least 150 kw and placed in service before January 1, 2014. For a webinar on QECBs, check out the Illinois Section of AWWA at

https://isawwa.site-ym.com/store/view_product.asp?id=1225800

MR. DAVID TUCKER I AM INTERESTED IN A MICO HYDRO POWER

IN THE 8/10 KW. I LIVE ON A FAIR CREEK WITH FAST MOVING

WATER. IT IS APPOX 12′ WIDE AND A DROP OF APPOX 20′

IN 100’IT WILL FI

LL A 5 GAL BUCKET IN 12 SECONDS. PLEASE

I WOULD LIKE TO TALK TO YOU. PLEASE SENT ME YOUR PHONE #

AND I WILL CALL YOU. IF I NEED TO TALK TO SOMEONE ELSE

PLEASE GIVE ME HIS NAME AND PHONE # THANK YOU

Robert, I saw your post and wanted to let you know of a Microhydro Workshop in Boone, NC that you may be interested in, http://energy.appstate.edu/workshops/253.

Dear All,

we have a water Resource of 4000 US Gallons (GPM) of water coming through 20 “inch DIA pipe with 5 bar pressure and we are looking Techno-commercial proposal for micro hydro power generation plant and Tentative Offer to Budget the the same my email id is anthonyamabraham@gmail.com and this will be installed in the U.A.E Dubai

To whom it may concern,

Hi, we are in the process of completing a large project which has a

well at about 60′ above lowest grade. Our needs are to produce

electricity with the most efficient systems such as a Micro-Hydro Power

and capable of supplying about 1,000-1,200 amps. Your assistance with further info. will be greatly appreciated.

Please, let me know if you need further info. from me.

Thank you

Have a great day,

Miguel Coronas

Designer

Web Site: http://cadcoron.blogspot.com/

Mobil: 1-(559)281-9189

Email: macoronas@gmail.com

Address: 1324 W Celeste,

Fresno, 93711, CA. USA